Reliable DOH & HPD Lead Violation Removal in NYC-- Protect Your Residential property

Reliable DOH & HPD Lead Violation Removal in NYC-- Protect Your Residential property

Blog Article

Vital Devices and Techniques for Reliable Lead Infraction Cleaning

Attending to lead offenses efficiently necessitates an extensive technique that blends the right tools with tactical approaches. The initial step includes equipping employees with Individual Safety Equipment (PPE) to secure their health and wellness. Concurrently, using specialized cleaning devices, such as HEPA vacuums and lead-specific cleaner, is necessary for comprehensive impurity elimination. Reliable containment approaches, consisting of plastic sheeting and negative air stress systems, are important to avoid the spread of hazardous materials. Furthermore, safe disposal practices and strict adherence to governing standards make certain accountable handling of toxic waste. However what are the nuanced methods that really make a difference?

Personal Protective Equipment

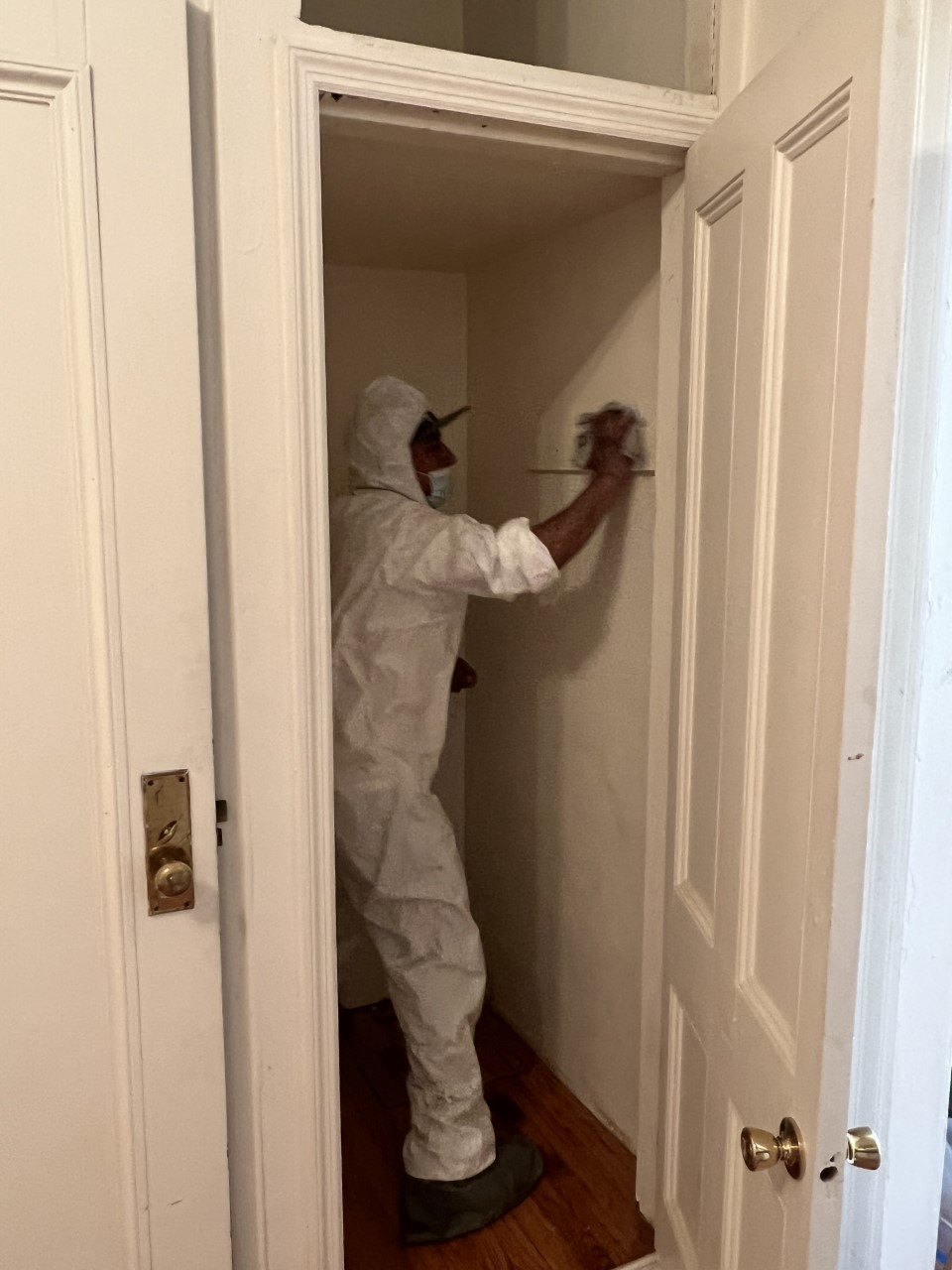

Individual safety tools (PPE) is a vital element in the efficient monitoring of lead contamination cleanup. The important PPE for lead clean-up includes respirators, safety garments, gloves, and eye defense.

Respirators, particularly those geared up with HEPA filters, are vital for filtering system air-borne lead bits, preventing inhalation. Correct fit and seal checks are critical to guarantee their efficiency. Safety clothing, consisting of coveralls and disposable fits, prevents lead dirt from adhering to workers' garments, lowering the risk of additional contamination. Gloves, generally made from nitrile or latex, shield the skin from straight contact with lead, while safety goggles or full-face shields safeguard the eyes from dirt and particles.

Furthermore, rigorous training on the right usage and maintenance of PPE is essential. Workers should be educated on putting on and doffing procedures to prevent contamination. Normal examinations and replacements of PPE parts are required to keep their protective capacities, making sure a secure and certified cleanup operation.

Specialized Cleaning Equipment

Another essential device is the wet/dry vacuum, which can effectively clean up both dust and fluid impurities. These vacuum cleaners commonly feature HEPA filters to give an extra layer of safety. Wet cleans or tack fabrics are also vital for surface area cleansing; they are specifically developed to capture and hold lead fragments, minimizing the risk of spreading out contamination.

For even more stubborn down payments, specialized lead-removal cleaner are needed. These agents are developed to break down lead particles, making them easier to remove. Scrub brushes with sturdy bristles can help in this process, especially on rough surfaces where lead dirt often tends to stick a lot more strongly.

In addition, encapsulants are used to secure lead-contaminated surface areas, protecting against the release of lead dirt. These specialized paints and investigate this site finishes are created to comply with different substratums, supplying a long-lasting option for lead control.

Effective Control Techniques

Effective control methods are important in minimizing the spread of lead contamination throughout cleanup tasks. Implementing durable control methods makes certain that lead particles do not move to untouched areas, thus protecting both employees and the atmosphere. One main approach is using plastic bed linen to seal off contaminated zones. Durable polyethylene obstacles can be installed from floor to ceiling to create a controlled work area, significantly reducing the threat of airborne lead dust dispersal.

To enhance containment, encapsulants can be related to surface areas that are not being removed or disrupted. These specialized coverings bind lead dirt, decreasing its availability for resuspension. Furthermore, all workers need to use proper Personal Safety Devices (PPE), including respirators and non reusable suits, to stop contamination spread.

Safe Disposal Practices

Guaranteeing secure look here disposal methods is a vital element in the management of lead contamination cleaning. Correct disposal minimizes the threat of lead returning to the setting and threatening public wellness. The initial step is to determine and set apart lead-contaminated waste from other materials. Safe and secure control utilizing sturdy, watertight containers is vital to prevent splilling during transport.

Delivering lead waste needs adherence to stringent standards. Utilizing accredited harmful waste carriers makes certain that the materials are taken care of responsibly. Paperwork, including shows up detailing the type and amount of waste, need to go along with shipments to track the waste from the site of origin to its final disposal location.

Designated unsafe waste disposal facilities are equipped to take care of lead-contaminated products safely. These facilities typically utilize sophisticated methods such as stablizing, solidification, or chemical treatment to neutralize the lead before disposal. Landfilling in specialized, lined locations that stop leachate from polluting groundwater is an usual practice for last disposal.

Normal training for workers associated with lead garbage disposal is vital to maintain safety and security requirements and protect against accidental direct exposure. By sticking to these methods, organizations can considerably minimize the environmental and health impacts linked with lead contamination.

Regulatory Conformity Tips

Complying with governing conformity is paramount in the successful execution of lead contamination clean-up. Comprehending and complying with federal, state, and neighborhood guidelines ensures not only the safety and health and wellness of individuals yet likewise the lawful and economic health of the cleaning company. The Environmental Defense Agency (EPA) sets stringent standards, such as the Lead Remodelling, Repair, and Painting (RRP) Policy, which mandates proper qualification and training for specialists taking care of lead-based tasks.

Conformity starts with a complete evaluation of relevant legislations and regulations. Organizations should stay upgraded on any kind of legal modifications, which can be assisted in with normal training sessions and signing up for market updates. Documentation is an additional important conformity element; maintaining in-depth documents of all activities, including evaluation records, employee training logs, and disposal materializes, is crucial.

Furthermore, engaging with certified lead examiners or risk assessors makes sure that lead hazards are correctly basics identified and mitigated. Employers should enforce using Personal Safety Equipment (PPE) and make sure that security procedures are purely complied with. Last but not least, transparent communication with stakeholders, including employees, clients, and regulative bodies, will cultivate a society of compliance and accountability, ultimately adding to a much safer and a lot more effective lead cleanup procedure.

Conclusion

Reliable lead violation clean-up demands the combination of specialized devices and critical approaches to guarantee safety and security and efficiency. Personal protective equipment (PPE) safeguards employees from exposure, while risk-free disposal practices and stringent adherence to regulative compliance are important for sensibly managing dangerous waste.

Report this page